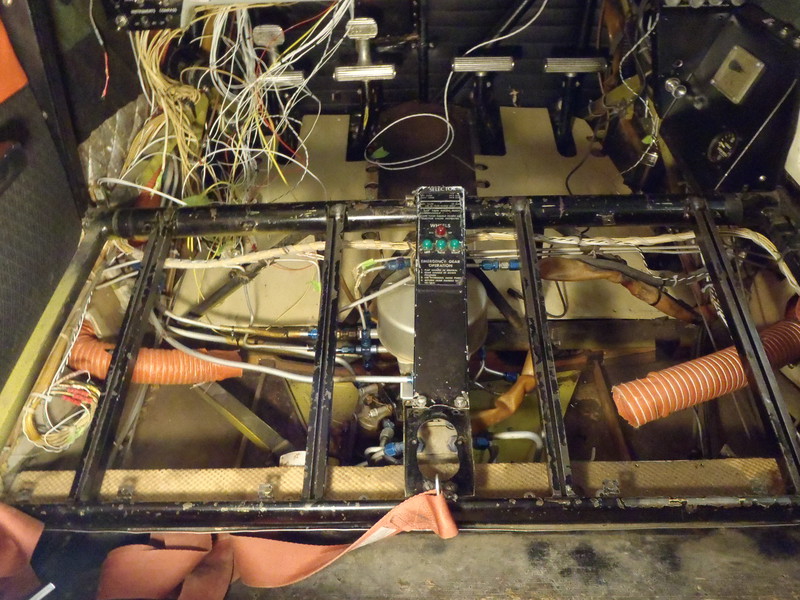

With some help from Jeff, the big accomplishment of the day was bleeding the hydraulic lines for landing gear. It only took 4 or 5 cycles of the gear to get everything bled, which was a pleasant surprise. Unfortunately, on the last swing of the day, the left gear safe light didn’t come on. After a bit of debugging, it turned out that the bulb burned out. The unfortunate thing is that it burned out between the second to last and last gear extension, so it was quite unexpected. The Bellanca doesn’t have a gear light test switch, so swapping bulbs is the only way to check for bulb operation.

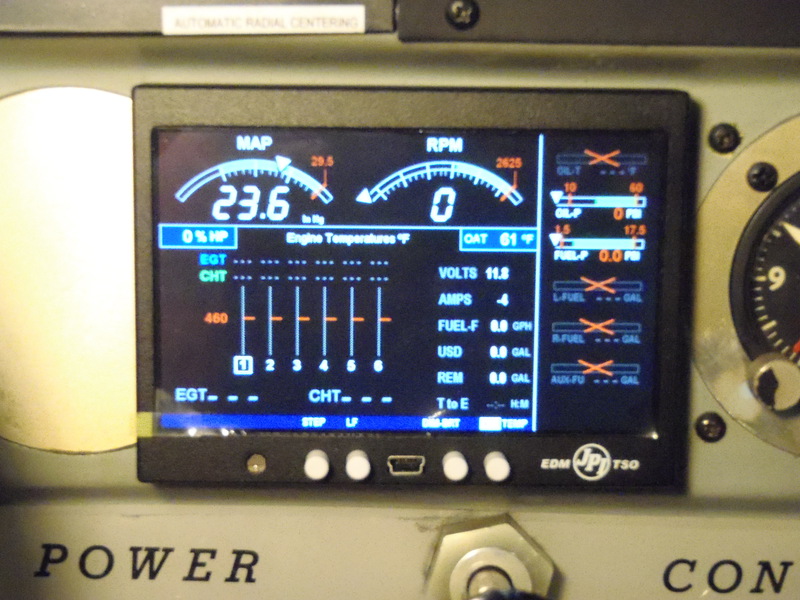

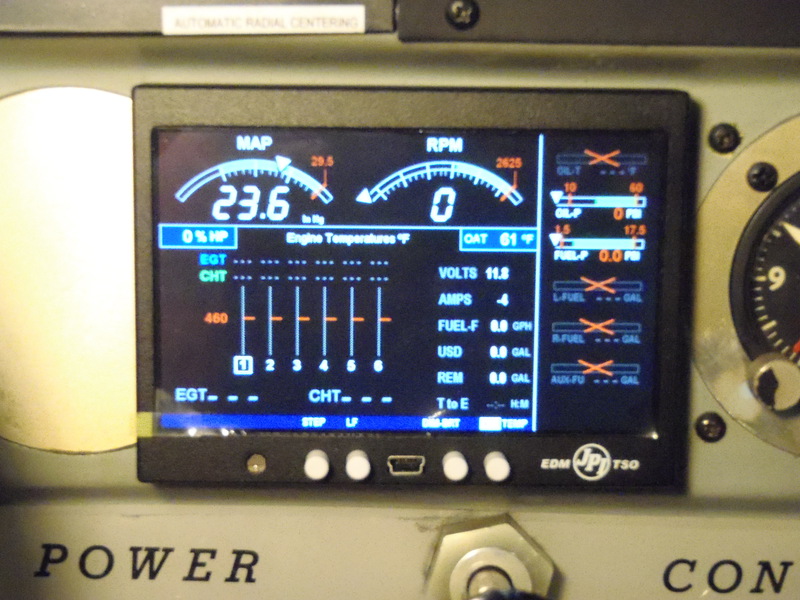

The outside air temperature (OAT), Manifold Pressure (MAP), and ammeter were successfully hooked up as well. The MAP was a bit tricky, as I had to bend and flare a 3/16″ aluminum tube and then build up a (very) short 1/4″ Aeroquip 303 hose. I had never done either before, so it was a bit of a learning experience. I also verified that all three fuel level sending units are talking to the EDM, so the fuel gauges will work once I do the fuel calibration.

After realizing I had made a silly mistake with the wiring of the starter circuit, the breaker panel is finished. Everything checks out and went back together fairly cleanly. I still have to install the parking brake control cable (the hole at the bottom of the of the little triangular plate next to the circuit breaker panel. Also need to get some white on clear labels and make up labels for the Avionics Master, the parking brake, and the intercom circuit breaker (the 2A breaker not part of the main panel). You can also see the back part of the OAT sensor and the radio selector for the autopilot.

Finally, the wire running across the left side of the panel is now back bundled together. The autopilot panel (the big hole under the left control yoke) isn’t quite finished yet; hopefully this weekend). I need to get some longer zip ties to finish securing all the cables behind the panel on the left side of the panel. The intercom (far right side) panel is out and has a hole for the Garmin power cable. The paint hopefully will be dry tomorrow morning and I can reinstall the intercom and Garmin tomorrow. I need to wire the Garmin into the EDM so that the EDM can display MPG and fuel remain at destination, but that doesn’t look too bad.